الاضواء

CNC Programmer, Manufacturing Engineer, CAM Software Developer, CNC Machinist, CAM Automation Engineer, CNC Applications Engineer, CAM Integration Specialist, CAM Team Lead, CAD/CAM Specialist

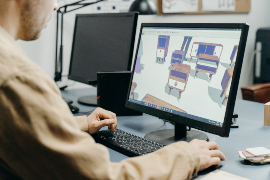

How does an idea for a product become a reality? The first step is to create a visual design of the product concept using computer-aided design (CAD) software. Once this virtual model is finished, it’s time to make the product’s individual parts using computer-aided manufacturing (CAM) software and Computer Numerical Control (CNC) manufacturing machines.

CAM Programmers work with the CAD and CAM software to tell the CNC machines how to cut, drill, mill and bore raw materials into whatever shapes the products’ parts need to be in. They oversee and quality control these processes so that the machines engineer parts within desired parameters.

As All3DP explains it, “CAM software prepares a drawing for production.” The software uses G-code programming language to translate CAD models into instructions that CNC machines can follow. It literally tells “motors where to move, how fast to move, and the programmed path they should follow,” while also checking for geometrical errors and calculating machine parameter adjustments.

- Programming software that makes vital parts needed to manufacture products

- Contributing to the economy by providing a steady stream of parts used in countless industries

“The most rewarding aspect of my career is undoubtedly my capacity to transform concepts into tangible realities. It is immensely gratifying to witness an idea evolve from its blueprint to a functional, spatial presence,” says Chris Lee, CAM Programmer for Hadrian. “My career is devoted to bolstering America's capabilities in [the manufacturing] sector, a pursuit that instills a profound sense of purpose and fulfillment.”

جدول العمل

CAM Programmers work full-time, with overtime necessary depending on goals and timeframes. Their duties are usually performed indoors in factories or shops, but work may require them to travel to various locations to complete on-site tasks.

واجبات نموذجية

- Review sketches, technical drawings, 3D computer designs, blueprints, and other reference files

- Review written descriptions and specifications of desired parts to be made

- Discuss final product needs, quantities, and costs

- Determine work processes sequence order

- Use computer-aided design software to render models for computer-aided manufacturing software

- Create or modify CAM programs to instruct machines

- Keep track of software changes. Ensure updates are compatible with machines

- Collaborate with CNC machine operators, or perform the operations as per the job description (some programmers are also machinists or operators)

- Perform online and offline CNC machine programming as needed

- Adjust machine components such as blades, holding fixtures, etc.

- Determine which blank types to use to create a workpiece

- Verify the tolerance of materials to be machined

- Create parts using processes such as turning, milling, drilling, shaping, and grinding

- Keep an eye on machine feeds and speeds

- Screen items for defects. Make adjustments to machinery as needed

- Use measuring instruments to determine the dimensions of the final fabricated pieces. Verify that completed products comply with requirements

- Diagnose machine errors and make minor repairs

- Store, label, and reference specification data

مسؤوليات إضافية

- Wear required personal protective equipment and follow established safety protocols

- Stay up-to-date on technical manuals

- Maintain technical documentation and spreadsheets of data

- Update material and consumable stock lists; order supplies

- Train and mentor new CAM Programmers, machinists, operators, and technicians

- Keep work areas clean and perform routine maintenance on machines

المهارات الشخصية

- Alertness

- Analytical

- Cautious

- Compliance-oriented

- التفكير النقدي

- المنحى التفصيلي

- Discipline

- منهجية

- صبر

- Planning and organization

- مهارات حل المشكلات

- الحكم السليم

- Stamina

- العمل الجماعي

- إدارة الوقت

المهارات الفنية

- Knowledge of G-code programming language and commands:

- G: machine motion

- M: miscellaneous machine action

- F: feeds

- S: speeds

- T: tools

- Computer-aided manufacturing software like Autodesk Fusion 360, SOLIDWORKS, Solid Edge, Siemens NX CAM, GibbsCAM, Mastercam, etc.

- Computer-aided design programs like Autodesk AutoCAD, CATIA, PTC Creo Parametric, and SolidCAM

- Procedure management programs like Hexagon Metrology PC-DMIS

- Familiarity with CNC machine tools (routers, water cutters, plasma cutters, laser cutters, milling machines, lathes, electrical discharge machines, etc.)

- Familiarity with tools and equipment such as micrometers, calipers, shapers, grinders, and drilling machines

- Familiarity with processes such as metalworking, brazing, heat-treating, and welding

- Familiarity with hydraulic systems, electrical wiring, lubricants, and batteries

- Familiarity with metal and metal alloys, including steel, brass, aluminum, copper, zinc, lead, vanadium, and manganese

- Machinery manufacturing/machine shops in a wide range of sectors

“Individuals pursuing a career in my field have the flexibility to explore opportunities across various types of organizations, ranging from large technology conglomerates to burgeoning startups,” Chris Lee notes. “With CAM programming skills being widely applicable, professionals can find rewarding roles in an array of industries that rely on manufacturing processes. These sectors may include, but are not limited to, aerospace, defense, commercial manufacturing, and prototype development.”

CAM Programmers are relied upon to write the instructions for CNC machines to produce products that conform to very precise specifications. Their work must be meticulous and error-free, as they consider multiple factors such as the right materials, tools, and equipment to use.

Manufacturing worksites can be loud, with numerous hazards to be wary of. Programmers who work directly with or around CNC machines must be conscious of all risks and wear appropriate personal protective gear, including goggles, hearing protection, and gloves, as needed.

Chris Lee provides an inside look: “A typical day for me begins with an in-depth review of the assigned project blueprint, focusing on identifying potential challenges or areas requiring specialized tooling and consideration. With a mental framework of my approach, I initiate a collaborative meeting with CAM programmers, CMM inspectors, and machine operators. We engage in a comprehensive discussion of the proposed strategies, addressing any additional concerns or potential obstacles.

Upon finalizing the most effective approach, I oversee the machine operation to produce the first article and submit it for inspection. Once the initial part is approved, I provide comprehensive work instructions to the operators to commence production. Concurrently, I manage any process errors that arise within our proprietary software or systems, diligently documenting and seeking solutions for the continual improvement of our processes. This ensures a seamless and efficient workflow, fostering an environment of excellence and innovation in our operations.”

An interesting trend that affects computer-aided manufacturing is 3D printing. Shops can now print parts that CNC machines can polish up and finish, which may impact the demand for CAM programming in the future. Meanwhile, there’s an increased demand for CAD and CAM capabilities to be integrated into single platforms (instead of relying on two different programs). Another trend is the use of CAM software digital twins that simulate everything a CNC machine will do. This allows the programmer to troubleshoot ahead of time and make adjustments before pushing the instructions to the actual CNC machine.

Some trends depend on the sector in which the CAM Programmer works. For example, Chris Lee outlines current trends in the aerospace industry. “As we witness the unfolding of a new space race, propelled by companies like SpaceX and their efforts to reduce orbital launch costs, the demand for skilled professionals in 5-axis programming has soared. Due to the intricate nature of the components involved in these cutting-edge projects, versatility and expertise across various machining processes are highly desirable.”

Chris also notes that programmers “with experience in 3-axis, 4-axis, and 5-axis machining, as well as turning, and mill-turn operations, possess a significant competitive advantage in the field.”

People who get into CAM Programming usually enjoy working with software as well as with their hands. They are safety-conscious and feel comfortable working around loud relatively dangerous machines. They might have enjoyed math and computer programming courses in high school or liked doing projects in shop classes.

“Individuals in my occupation often exhibit a passion for creating and building from a young age,” Chris Lee explains. “This enthusiasm may manifest through various mediums, such as paper crafts, plastics, or metalwork. Engaging in a wide range of interests and hobbies contributes to shaping a multifaceted mindset. Exposure to diverse experiences allows individuals to develop versatile problem-solving skills and innovative approaches, which are crucial in a dynamic field such as ours. Embracing these myriad interests and pursuits not only enriches one's personal life but also cultivates essential abilities that translate seamlessly into a successful career in this industry.”

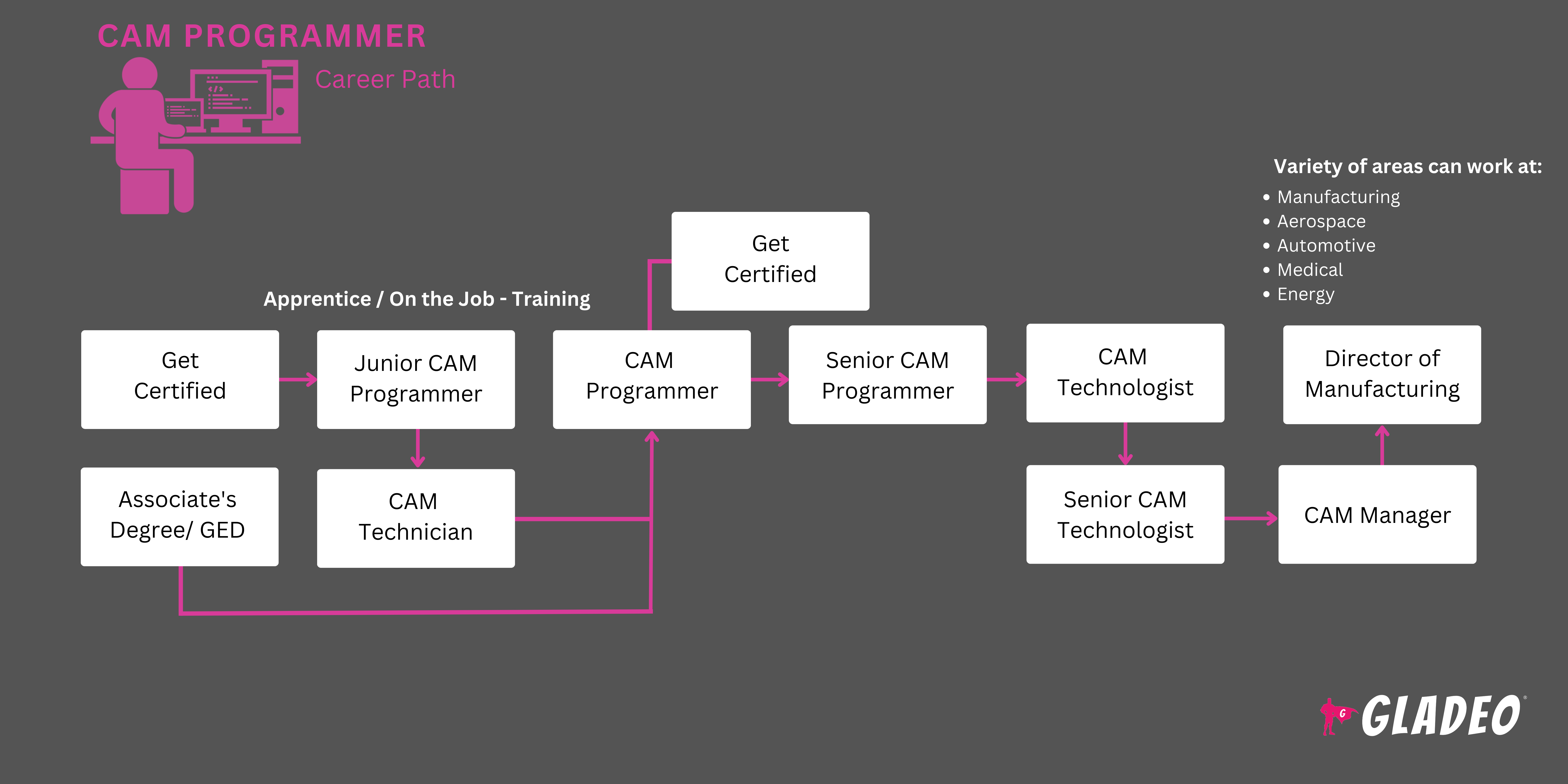

- CAM Programmers need at least a high school diploma or GED, but a bachelor’s degree is not required

- Many workers in this field pursue a CAD/CAM bootcamp, certificate, or associate’s degree at a community college or technical school. Common courses include:

- Blueprint reading

- CAM programming and G-code

- CNC machine usage

- Computer-aided design

- Coordinate measurement

- Dimensional metrology

- Jig and fixture design

- Lathe Programming

- Math (calculus, trigonometry, linear algebra, geometry, statistics)

- Mechanical drafting with CAD

- Milling applications and programming

- Shop safety

- Tooling and machining

- Turning applications

- Welding and metal joining

- Students can learn a lot from online courses such as Autodesk’s 19-hour Intro to CAD, CAM, and Practical CNC Machining offered via Coursera. There’s also a four-month Autodesk CAD/CAM for Manufacturing Specialization which includes a hands-on project!

- Employers often look for a strong mix of academics and practical work experience. Well-qualified candidates may receive additional On-the-Job training or apprenticeship opportunities

- Optional certifications can help CAM Programmers qualify for advancement. Certifications options include:

- National Institute for Metalworking Skills - CAM Turning I or CNC Lathe Operations

- Association of Energy Engineers- Certified Measurement and Verification Professional

- There are also manufacturer and software-specific certs available

“Formal education is not always a prerequisite for success,” says Chris Lee. “Demonstrating a deep understanding and practical proficiency in the field can often outweigh the value of traditional education. This notion is reinforced by the limited availability of academic programs that concentrate specifically on the manufacturing process, as many courses tend to emphasize engineering principles and theoretical frameworks. Consequently, the ability to showcase tangible expertise and hands-on experience becomes a more significant factor in determining one's qualifications and readiness to excel in this dynamic and ever-evolving sector.”

- CAM Programmers should consider if they want to complete a certificate or associate’s at a technical school or community college

- Consider the cost of tuition, discounts, and local scholarship opportunities (in addition to federal aid)

- Think about your schedule and flexibility when deciding whether to enroll in an on-campus, online, or hybrid program. Some courses may be better done in person to get hands-on experience

- Sign up for plenty of math (arithmetic, algebra, geometry, and trigonometry), physics, computer science, materials science, and shop classes in high school

- Consider learning mechanical drawing and blueprint reading

- Take online CAD/CAM courses from Coursera, Udemy, edX, Pluralsight, LinkedIn Learning, or other sites

- Enroll in a community college or vocational/technical school program to learn about CAD, CAM, and CNC machining

- Gain real-world experience via part-time jobs related to machining or shop work

- Start crafting your resume and add to it as you learn and gain work experience

- Review job postings in advance to see what the average requirements are

- Request to do an informational interview with a working CAM Programmer or CNC machinist

- Make a list of your contacts (including email addresses or phone numbers) who might serve as future job references

- Study books, online articles, and video tutorials related to CAD, CAM Programming, and CNC machining

- Join online forums to ask questions and learn from experienced programmers

- Engage with professional organizations to learn, share, make friends, and grow your network

Chris Lee suggests that “Students in high school and college should adopt an exploratory mindset and actively seize opportunities to broaden their experiences. Engaging in diverse activities and projects can help determine one's interests and preferences, providing valuable insights for future pursuits. Embracing both success and failure is essential, as understanding the reasons behind an outcome often leads to accelerated learning and personal growth."

“With the advent of the Internet, students now have access to a wealth of knowledge and resources that can enhance their skills and understanding. Utilizing platforms such as YouTube for tutorials and guidance can foster creativity and problem-solving abilities. Additionally, networking through social media platforms can connect students with industry professionals who appreciate and encourage curiosity. Engaging in meaningful conversations with experienced individuals can not only provide valuable insights but also potentially lay the groundwork for important professional relationships in the future.”

- Check out job portals such as Indeed, Simply Hired, Glassdoor, and Craigslist

- Get as much practical shop work experience under your belt as you can before applying

- Consider enlisting in the military in a machinist career field. You’ll get free paid training and can earn job experience which can be used in either a military or civilian career

- Seek out apprenticeships sponsored by employers, unions, or trade associations

- Ask working CAM Programmers and CNC machinists for job-seeking tips

- Consider getting a certificate or an associate’s degree. Academic credentials may help you stand out against the competition

- Ask your school’s career center for help connecting with recruiters and job fairs

- Ask potential references in advance to see if they’ll recommend you or write letters of reference

- Check out online resume templates and review potential job interview questions

“It is essential to demonstrate a proactive approach and an unwavering commitment to excellence,” advises Chris Lee. “This means not only being physically present but also exhibiting readiness to work, learn, and grow professionally. Display genuine enthusiasm and passion for the field, as these traits will resonate with potential employers."

“Honesty and integrity play pivotal roles in the job search process. Be transparent about your skills and limitations, refraining from embellishing your resume. Employers appreciate candor and will make informed decisions about your suitability for a role. Recognize that, as a newcomer, you may require guidance and training, and express gratitude for the opportunity to learn and contribute."

“Developing and showcasing a diverse range of relevant skills will further enhance your chances of success. By combining a proactive attitude, a hunger for knowledge, and a foundation of pertinent abilities, you will be well-positioned to embark on a rewarding career in any industry.”

- Study manufacturer and software guides. Become an expert on the programs and machines you use

- Pay attention and take notes during any OJT you’re offered

- Follow procedures and ensure your programming results in accurately manufactured parts

- Demonstrate that you can be trusted to work independently

- Ask your supervisor how you can improve your CAD, CAM, and CNC machine knowledge and skills to better serve the company. If they suggest doing a certification, knock it out (but see if they’ll pay for it)

- Learn all you can from programmers with more experience than you. However, don’t take shortcuts or pick up bad habits. Be sure to follow procedures as directed by your employer

- Collaborate effectively on teams and focus on solving problems

- Demonstrate leadership by setting an example for others to follow

- Train new workers patiently and thoroughly. Make sure to always wear appropriate personal protective equipment to avoid mishaps as well as less obvious hazards such as hearing damage

- Stay engaged with professional organizations and unions, such as the International Association of Machinists and Aerospace Workers

In conclusion, Chris Lee suggests the following: “Remember that your attitude can be the key determinant of success in this field. Embrace the principle that it's not solely about what you know, but rather how you utilize and apply your knowledge. Maintain a humble demeanor and an open mind, welcoming every opportunity that comes your way. Exploring new experiences can lead to valuable learning and growth, enriching both your personal and professional life."

“Do not hesitate to admit when you don't have an answer but strive to develop the skills and resourcefulness needed to find solutions to challenges. Recognize the importance of teamwork and the value of relying on your colleagues to bridge knowledge gaps. This collaborative approach will contribute to your growth and make you a stronger candidate in the job market."

“Ultimately, the most sought-after companies are interested in your problem-solving abilities and thought processes rather than an encyclopedic knowledge of every subject. Acknowledging this fact and focusing on cultivating a growth mindset, adaptability, and strong collaboration skills will set you on a path to success in this dynamic and rewarding industry.”

المواقع الإلكترونية

- 3Ds Max

- American Mold Builders Association

- Association for Manufacturing Technology

- Association of Energy Engineers

- AutoCAD

- Autodesk Fusion 360

- Autodesk Inventor

- Blender

- CATIA

- Fabricators & Manufacturers Association, International

- G2.com

- IMAGINEiT

- International Association of Machinists and Aerospace Workers

- International Council for Machinery Lubrication

- International Fluid Power Society

- Manufacturing.gov

- Manufacturing Institute

- National Institute for Metalworking Skills

- National Tooling and Machining Association

- NX – Unigraphics

- Precision Machined Products Association

- Precision Metalforming Association

- Revit

- SketchUp

- Solid Edge

- SOLIDWORKS

- TITANS of CNC Machining (YouTube)

- Unity 3D

الكتب

- Computer Aided Design and Manufacturing, by Zhuming Bi and Xiaoqin Wang

- Hot Tech Cold Steel: How Computer-Aided Manufacturing Caught Fire in Ann Arbor and Spread Around the World, by Charles S. Hutchins and Stephanie Kadel Taras

- Math for Machinists, by Mark W. Huth

In terms of resources, Chris Lee suggests using social media to network and YouTube to learn. “In addition,” he writes, “consider seeking hands-on experiences within your local community. Approach businesses or workshops in your area and offer to help with tasks such as cleaning or organizing in exchange for an opportunity to learn and observe. Not only can this initiative lead to valuable learning experiences, but it may also result in potential job offers, as employers appreciate a proactive and dedicated attitude. Embrace creativity and be resourceful.”

Many CAM Programmers find the work interesting, but sometimes the job can get monotonous after a while. If you’re interested in exploring similar occupations, we suggest the following to consider:

- Boilermaker

- صائغ

- Graphic Designer

- Industrial Designer

- Industrial Machinery Mechanic

- Lathe and Turning Machine Tool Setter

- Metal and Plastic Machine Workers

- Millwright

- Tool and Die Maker

- Welder

ملف الأخبار

وظائف مميزة

الدورات والأدوات عبر الإنترنت